XMPRO-10 PLC

Made in India. Made for the world.

Messung proudly presents a groundbreaking series of cost-effective PLC controllers, specifically

engineered to deliver exceptional performance and user-friendly functionality. Unveiled as part of

Messung’s visionary ‘Navonmesh-Make in India initiative,’ XM-PRO 10 sets new standards as a compact,

versatile, and fully customizable device. Its capabilities are further enhanced by a comprehensive

selection of Local I/O and Remote I/O modules, ensuring effortless expandability.

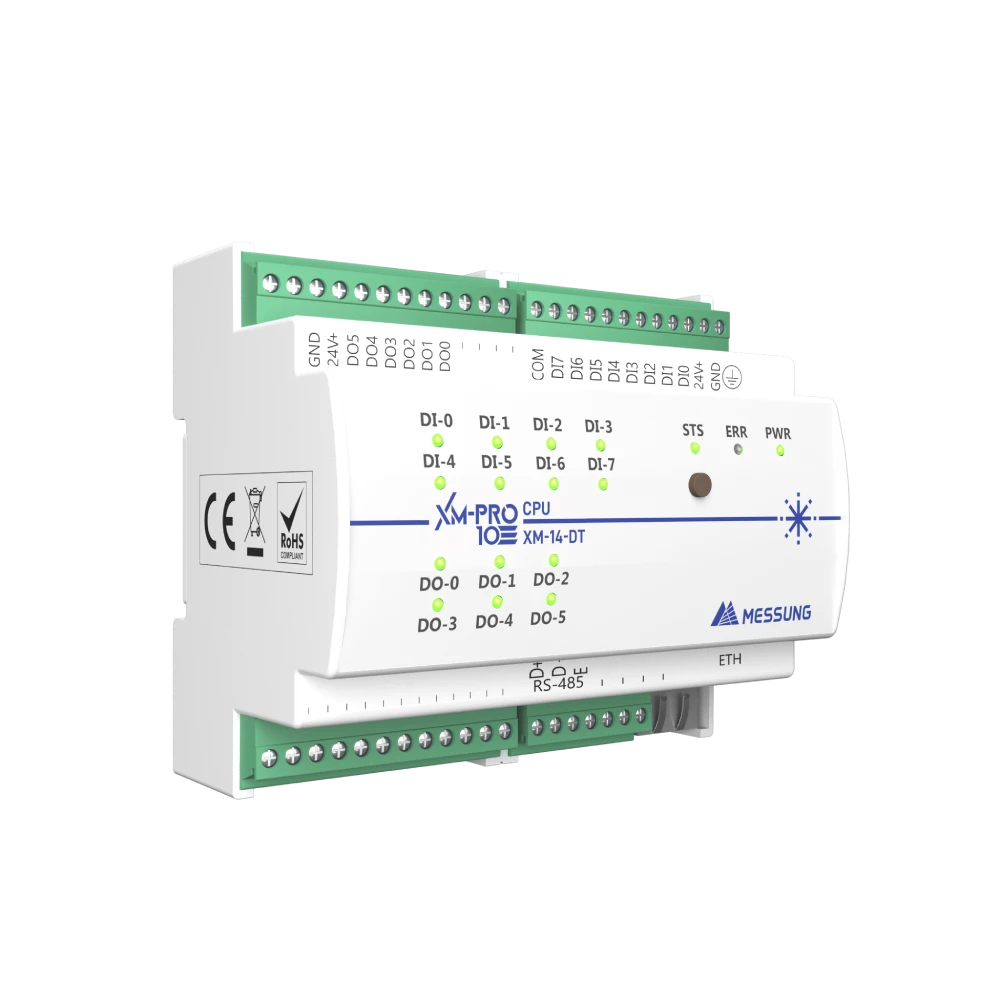

XM-14-DT

XM-17-ADT

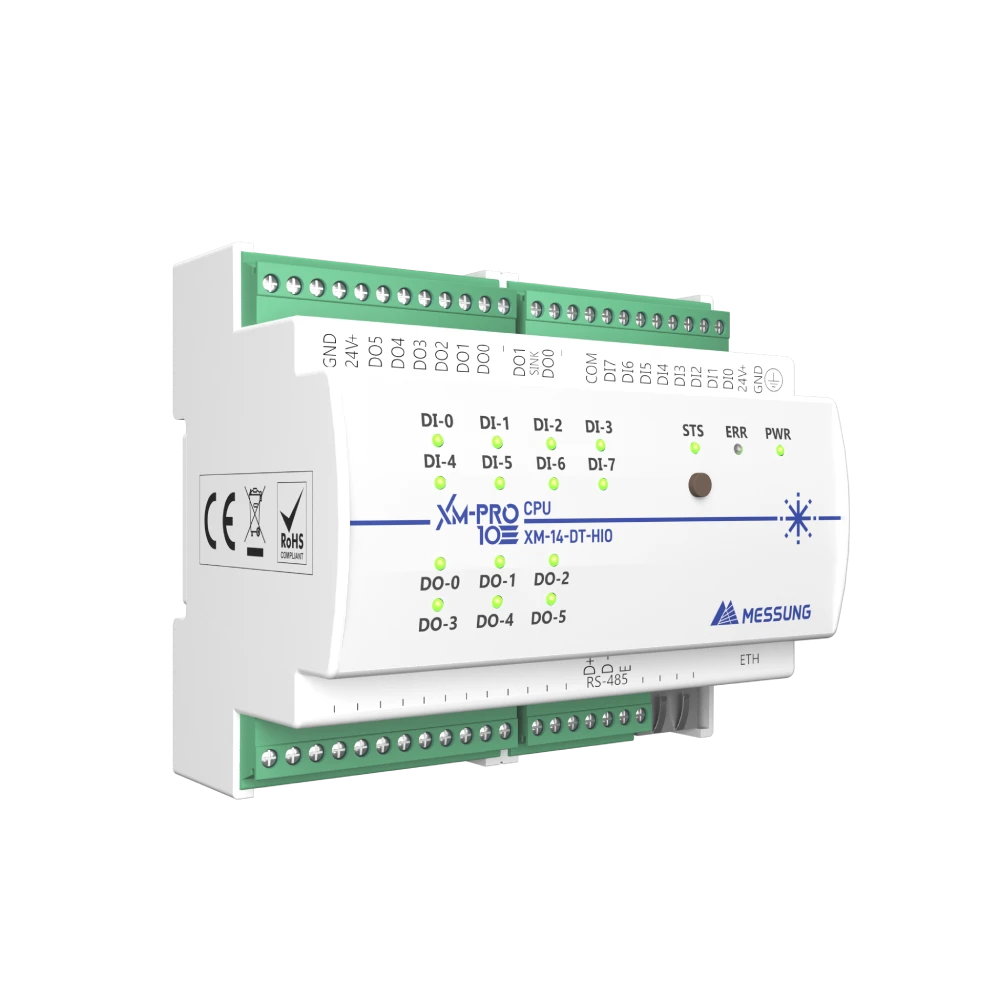

XM-14DT-HIO

XMPRO-10 Expansion Modules

-

XM-UI4-UO2

- Easy expansion by using a plug-in bus connection between the PLC and XM-UI4-UO2 module.

- Easy fitment next to the PLC on the 35 mm DIN rail.

- Bus connection routed through an expansion module connector that also offers protection for cable.

- Powered by an external power supply of 24 VDC.

- Convenient stacking of multiple expansion modules with connectors available on both sides of the XMUI4-UO2 unit.

-

XM-AI2-AO2

- The XM-AI2-AO2 is a 2 channel Analog Inputs and 2 channel Analog Outputs Expansion Module that can be installed at right side of XMPro-10 PLC through a BUS connector.

- This module offers 2 individually configurable voltage or current analog inputs and 2 individually configurable voltage or current analog outputs with easily pluggable wiring terminals.

- Depending upon the number of Analog I/Os in the application, this module can be selected as an expansion to On-Board IOs of the XMPro-10 series PLC.

-

XM-DI8-DO6T

- The XM-DI8-DO6T is an 8 channel Digital Inputs and 6 channel Digital Outputs Expansion Module that can be installed at right side of XMPro-10 PLC through a BUS connector.

- This module offers opto-isolated sink/source type inputs and transistor source type outputs with easily pluggable wiring terminals.

- Depending upon the number of Digital I/Os in the application, this module can be selected as an expansion to On-Board IOs of the XMPro-10 series PLC.

-

XM-DO-16T

- Easy expansion by using a plug-in bus connection between the PLC and XM-DO-16T module.

- Easy fitment next to the PLC on the 35 mm DIN rail.

- Bus connection routed through an Expansion Connector that also offers protection for cable.

- 16 solid-state transistor source output to drive external relays.

- Power supply connection on top as well as bottom for convenience of connection.

- Convenient stacking of multiple expansion modules with connectors available on both sides of the XM-DO-16T unit.

-

XM-DI-16

- Easy expansion by using a plug-in bus connection between the PLC and XM-DI-16 module.

- Easy fitment next to the PLC on the 35 mm DIN rail.

- Bus connection routed through an Expansion Connector that also offers protection for cable.

- 16 optically isolated digital inputs that can accept sink or source logic in 2 groups of 8 inputs.

- No external power supply required for the XM-DI-16 which is energized from the bus itself.

- Convenient stacking of multiple expansion modules with connectors available on both sides of the XM-DI-16 unit.

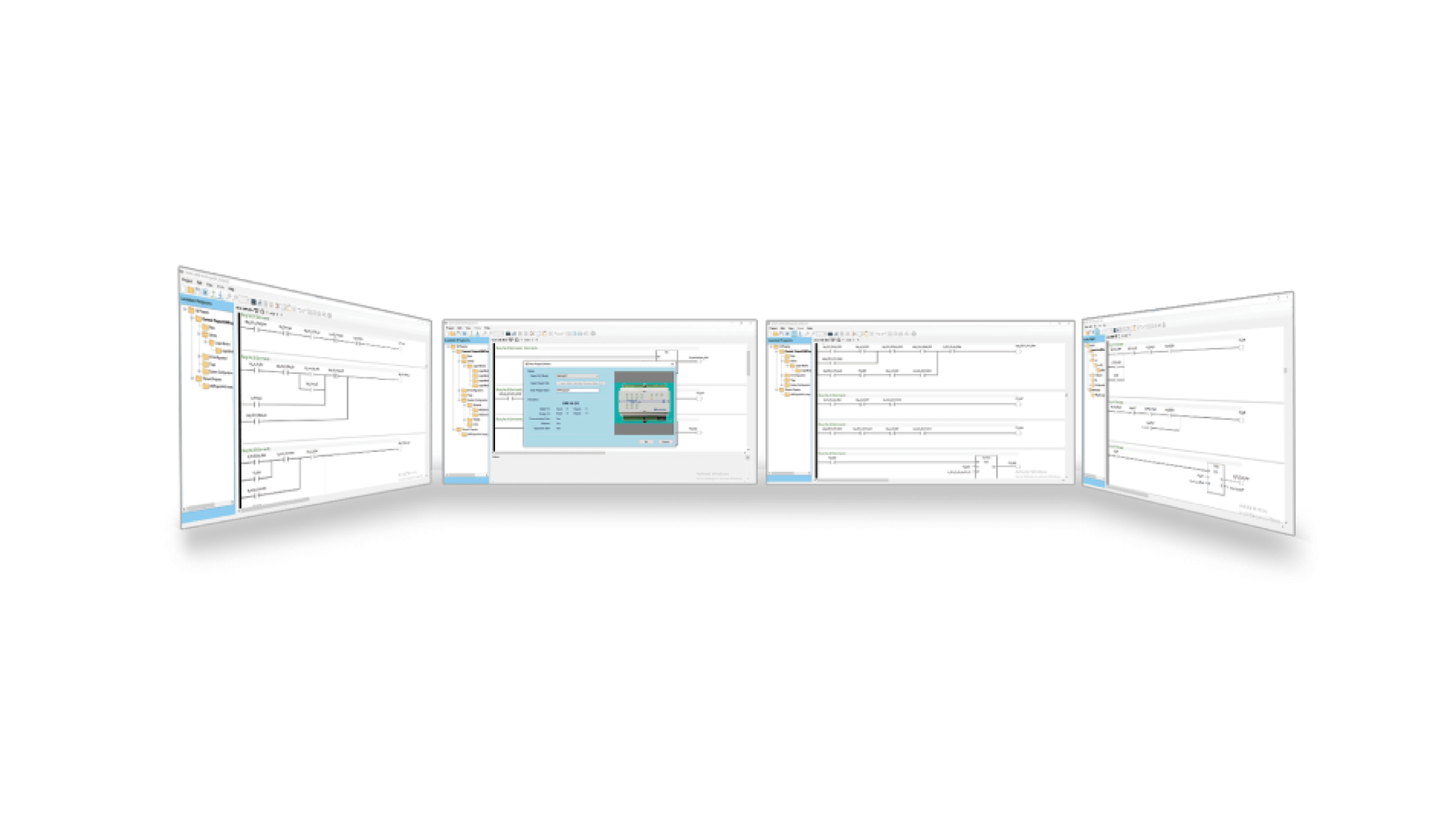

XMPS-2000 Software

A Windows-basedutility

User friendly environment for

better experience with software tools

Programming flexibility making itcompatible with varied range of application

Standard Programming Language LADDER

Online diagnostics functionality for runtime status

XMPRO-10 PLC Programming by powerful yet intuitive XMPS 2000 software.

- CPU & IO Modules Hardware configuration.

- Supports ladder programming languages ( LD ).

- Logic Blocks : Subroutines that can be called in Main block.

- Monitor Table: User defined Tags, Communication Variables and Watch window for real time monitoring field values of discrete and analog IOs.

- Online monitoring of Ladder program and generation of Cross

references. - “Force of value” possible during program testing.

- User Library: User defined function blocks for customised tasks or

specific applications.

- Task: Supports cyclic program execution , however I/O interrupt, timer interrupt and external interrupt shall be available in forthcoming software versions.

- User friendly configuration communication protocols

MODBUS TCP & RTU. - Simple way to configure IO’s in the software.

- System generated IO addresses.

- Online hardware diagnostics (CPU,IO ,Com ports etc.. status ).

- RTC (Real Time Clock) accessible through software.

- Availability of Standard Data types and Instruction sets.

- Upload/Download of user program through Ethernet port

Note: Rotate for 3D View.